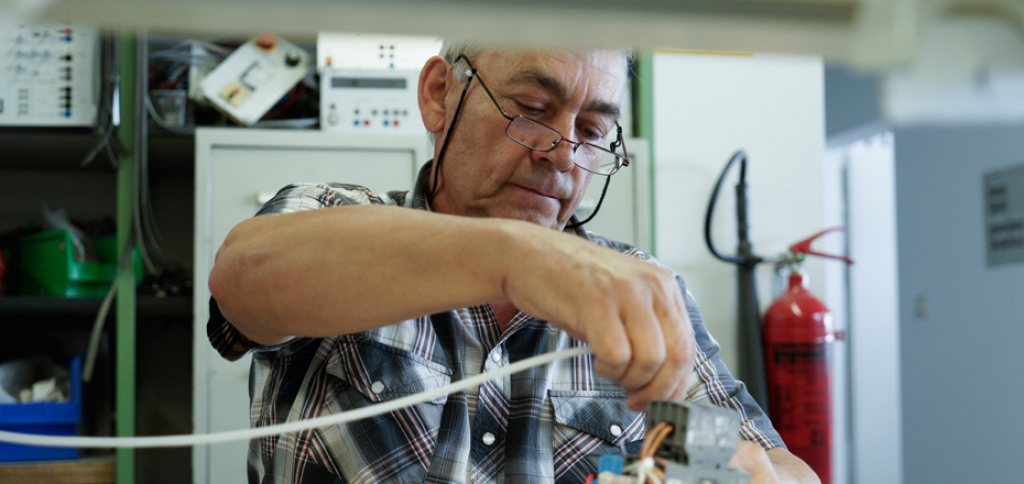

Andreas Fischer's unwavering entrepreneurial spirit was brought to life by his father Ernst Fischer (whom the company was named after) from childhood on. ... Ernst Fischer gradually turned a classic industrial workbench construction into a highly specialized manufacturer of integrated workplace systems.

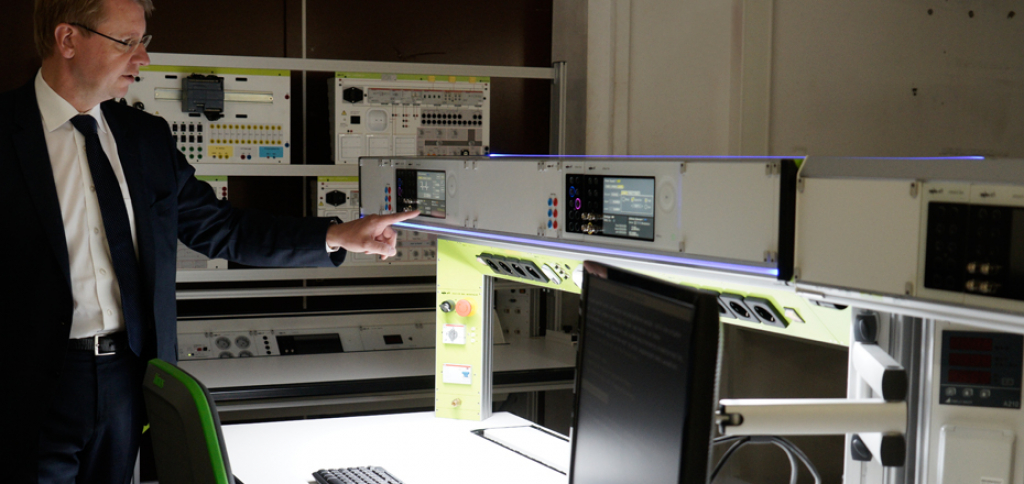

His customers were interested in built-in electronic measuring and testing devices? Fischer did it. "Our electronic laboratory tables have triggered a real revolution," enthuses Andreas Fischer today. Electrical engineers, microsystems and communications engineers joined the team. erfi began to serve the automotive industry and expanded its business. "Every part has to be electrically safety-tested." So Fischer had test systems developed and built for electrical safety and functional testing. "Suddenly we realized that this requires the right software." So the company patriarch founded his own software department.