Your system supplier for medical device manufacturing

erfi designs, develops and builds complex test facilities and test systems according to customer-specific requirements for medical device manufacturers. For many decades, we have specialised our products regarding to the high demands in the field of medical technology and have developed extensive test equipment for complex medical devices. In addition to the hardware, erfi offers variants of several test software specially adapted to medical technology, which enable operation by means of touchscreens. In addition, we supply, among other things, compact test systems with test hoods and contacting devices to accommodate all conceivable medical devices of various sizes.

Medical Technology Laboratories by erfi

– erfi hybrid

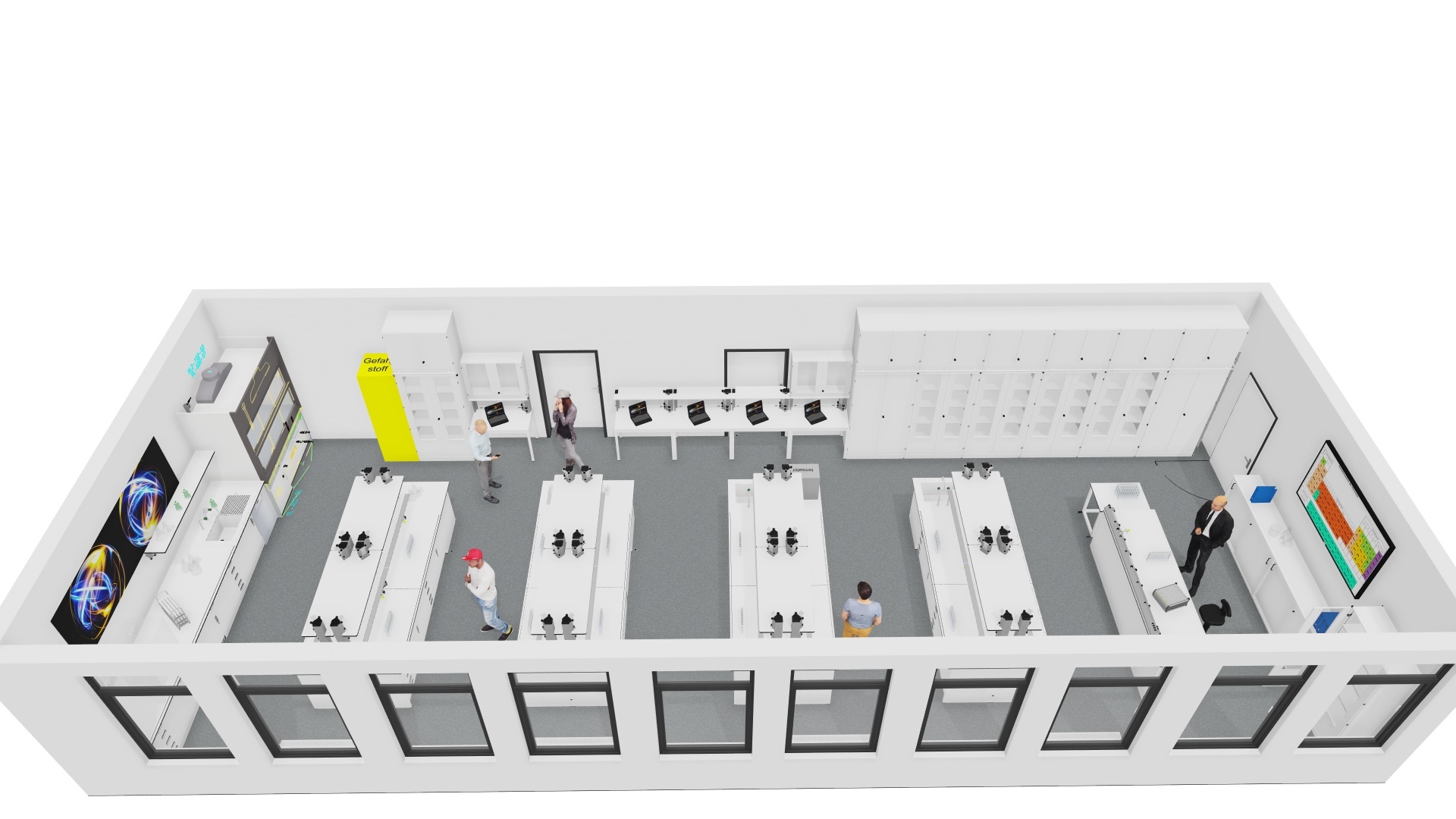

Decades of experience in workstation planning and implementation — with full consideration of all technical and ergonomic requirements — have established us as a system supplier.

With our product portfolio, we meet the growing demand for wet labs as well as chemical and physical laboratory equipment, including fume hoods, through the erfi hybrid furniture series.

It consists of a solid steel substructure combined with modern, contemporary aluminum frames in L- and triangular shapes. The laboratory program is complemented by erfi Mobile, enabling flexible positioning of medical devices and components.

Work Surfaces, Connections, and Supply

The work surface material is selected according to the specific requirements of the wet lab and may consist of solid core, solid core Trespa TopLab+, polypropylene, or even stoneware. These materials are highly resistant to chemicals, even with prolonged exposure.

Connections for water or components such as eye showers, sinks, draining surfaces, and dishwashers are integrated directly into the lab benches.

The horizontal energy supply (usually implemented as a wall duct) and the vertical energy supply are designed to accommodate all types of media. All horizontal and vertical supply channels—for water, various gases, compressed air, or electricity—are integrated via the profiles of the modular elneos® hybrid workstation system.

A key advantage of the profiles used is the easier access, made possible by the ergonomically angled placement of all connections.

Lighting and Storage

Invisible integration of the HCL workplace lighting is made possible by the special Toplight profile of the erfi hybridworkstation series, positioned beneath the storage shelf.

Below the work surface, extensive drawer systems (wide-wall and narrow-wall drawers) as well as small cabinets provide storage for equipment and utensils. In addition, large storage cabinets are available in various designs and with different interior fittings, including acid and alkali cabinets. The shelving systems typically consist of laminate wood shelves and glass.

Safety and Standards

To ensure safe working conditions in laboratories, we supply fume hoods exclusively according to the DIN EN 14175 standard. With our modern Highlinkpower software, various voltage levels and all types of media can be safely and easily activated remotely and selectively.

Room Layout and Planning

Our expertise in workplace and laboratory planning is incorporated into three-dimensional visualizations. Using specialized visualization software, we create various room layout options to closely approach the final design and realization.

erfi Mobile for Medical Laboratories

The erfi Mobile laboratory carts are a valuable addition to laboratories as well as clinical settings. They provide extra storage space and make handling various devices and components easier. These carts are versatile in their configuration, easy to clean, and ergonomically designed for comfortable use.

Maintenance and calibration

In addition to supplying customers in the medical technology segment, hospitals and clinics with test equipment, we also take care of the on-site maintenance and calibration of the test system, so that the devices are immediately ready for use again

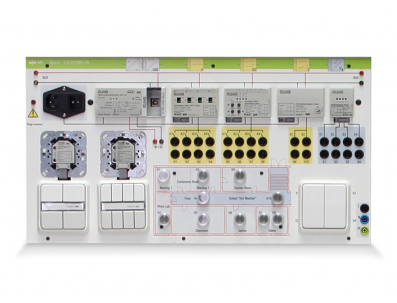

erfi test facilities include, among others: the following standardised components:

Compact tester with high-voltage, insulation, conductor resistance and leakage current testing, housing and ground leakage current testing incl. the 1. required in medical technology Failure.

In addition:

- Extended protective conductor first error simulation

- Leakage current test with application part type BF

- High-voltage switching matrixes with any number of high-voltage test points

- A large test chamber (shield) for appropriate small and large test specimens

- Test item connections for Europe, Brazil, USA (hospital) and other countries

Customer references

Manufacturers of anaesthesia and anaesthesia equipment

- Drägerwerk AG & Co. KGaA (Breathing Equipment)

- Respironics Deutschland GmbH (Breathing Equipment)

Manufacturers of defibrillators

- Philips Medizin-Systeme GmbH (Defibrillators)

- Metrax GmbH (Defibrillators)

- GS Elektromedizinische Geräte G. Stemple GmbH (Defibrillators)

Manufacturer of imaging equipment

- Philips Medizin-Systeme GmbH (Monitors)

- Carl Zeiss Microscopy GmbH (Microskopy)

- Leica Microsystems GmbH (Light Microscopy)

- Karl Storz SE & Co.KG (Endoscopy)

- Richard Wolf GmbH (Endoscopy)

- Dürr Dental AG (X-ray Machines))

Manufacturers of surgical equipment

- Brainlab AG (Neurosurgery, Digital Spinal Surgery, ENT/MCG Surgery)

- Aesculap AG (Surgical Instruments, Hair Clippers)

- Henke-Sass, Wolf GmbH (Surgical Instruments)

- B. Braun Melsungen AG (Laparoscopic Instruments)

Manufacturer of medical equipment

- Thermo Fisher Scientific Inc. (Temperature cabinets)

- Trilux Medical GmbH+Co. (surgical lights)

- Andreas Hettich GmbH & Co.KG (blood centrifuges)

Manufacturer of dental technology systems

- Dürr Dental AG (digital diagnostics, tooth preservation systems, suction systems, and compressors)

Kontaktformular

Ich stimme zu, dass meine Daten gemäß der Datenschutzerklärung elektronisch erhoben und gespeichert werden.