Innovative assembly systems: efficiency and adaptability

- Increased efficiency through modern assembly systems

- Flexibly adaptable production solutions

Ergonomic workplace design for employee health - Integration of artificial intelligence (AI) for future-proof systems

- Responsible and sustainable production methods

Industrial production is undergoing a period of change. Globalization and technological advances are forcing companies to constantly rethink and adapt their assembly systems.

erfi offers customized solutions that not only meet current requirements, but also integrate future-oriented technologies. From the optimization of existing systems to the implementation of the latest innovations, erfi helps companies to make their production more efficient and flexible.

Basics of assembly systems

Assembly systems encompass all processes of assembling components into a finished product. VDI Guideline 2860 describes assembly as an independent production stage that has undergone significant, albeit often gradual, further development since the introduction of assembly line assembly by Henry Ford in 1908.

With his scientific management methods, Frederik Winslow Taylor laid the foundation for today’s optimization of production processes. Modern assembly systems integrate advanced technologies that make both manual and automated processes more efficient by using innovative materials, automation techniques and digital control systems.

Montagesysteme Definition:

Assembly systems are structured processes that enable the assembly of individual parts into a complete product. They integrate both manual and automated techniques to ensure efficiency and accuracy in production.

Influence of global market conditions

Globalization has fundamentally changed the production landscape in recent decades. Companies must adapt to changing market conditions, which are characterized by intense competition and a high demand for product diversity.

The transition from a supplier’s market to a buyer’s market has increased product diversity and reduced production sizes. Assembly systems must therefore be adaptable in order to react quickly to market fluctuations and minimize production costs at the same time.

This requires investment in technologies that enable a rapid changeover in production and in training for employees so that they can use the new systems efficiently.

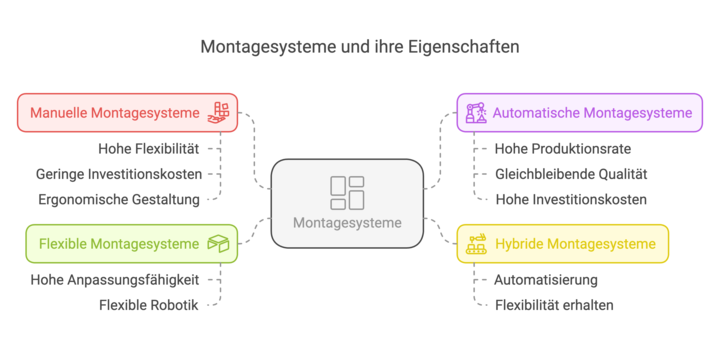

Types of mounting systems

manual assembly systems

In manual assembly systems, people are the key players. These systems are particularly common in industries where flexibility and adaptability to individual customer requirements are in demand.

There is potential for optimization in the improvement of ergonomic working conditions and employee training. A well-designed working environment can increase productivity and protect workers’ health.

Remember:

In manual assembly systems, the focus is on flexibility, with people playing the central role.

Automatic assembly systems

Automated assembly systems are designed for mass production and use specialized machines that often have modular structures. These systems enable a high production rate and consistent quality.

The degree of automation is determined by technical feasibility, cost and system reliability. The integration of sensors and real-time data processing improves control over the production process and enables a rapid response to deviations.

Hybride Montagesysteme

Hybrid assembly systems combine manual workstations with automated processes in order to utilize the advantages of both approaches. They are particularly suitable for medium-volume production and can be flexibly adapted to different requirements.

These systems are ideal for automating certain, frequently recurring work steps while retaining the flexibility of manual work. This helps to increase productivity and reduce production costs, while humans continue to play a central role in the process.

Remember:

Hybrid assembly systems offer the perfect balance between flexibility and automation.

Flexible Montagesysteme

Flexible assembly systems rely on programmable robots and intelligent control systems to assemble different product variants in any order.

These systems compete with manual assembly systems by offering a high degree of adaptability. The cost of the peripheral equipment required for the assembly and removal of products can exceed the basic cost of assembly robots.

An economical solution is often a hybrid system that combines the benefits of both man and machine to maximize efficiency while maintaining flexibility.

Innovations and future trends

- Artificial intelligence improves adaptability

- Modular systems offer cost efficiency

- Flexible robot solutions enable rapid production adjustments

The future of assembly systems will be characterized by the integration of new technologies. Artificial intelligence (AI) and machine learning enable assembly systems to optimize themselves and adapt to changes in real time. These technologies significantly improve the efficiency and flexibility of production processes.

In addition, modular systems and flexible robot solutions offer companies the opportunity to adapt their production to new requirements quickly and cost-effectively. erfi remains at the forefront of these developments by continuously investing in research and development.

Sustainability and quality management

Sustainability is an essential part of modern assembly systems. erfi relies on environmentally friendly materials and processes to minimize its ecological footprint.

A robust quality management system ensures that all products meet the highest standards and are environmentally friendly at the same time. By implementing sustainable practices into the production process, erfi helps to protect the environment while ensuring product efficiency and quality.

Discover the future of assembly with erfi

Are you ready to take your production processes to the next level? With erfi’s innovative and customized assembly system solutions, you can make your production more efficient and flexible. Let us convince you of our expertise in ergonomic workplace design and state-of-the-art technology.

Get in touch now!

FAQ

There are manual, automatic, hybrid and flexible assembly systems. Manual systems rely on human labor, while automatic systems use machines for mass production. Hybrids combine manual and automated processes, and flexible systems use programmable robots for adaptability to different product variants.

They optimize the production process by efficiently designing the assembly of components into finished products. They are used to increase productivity, implement adjustments quickly and maintain consistent quality, which is particularly important in highly competitive industries.